YOUR RELIABLE MOULD MAKER

Mould making is our core business and the base for what we do.

Our capacity: 480 moulds per year stretching from 50 Kg to 10 Tons depending on mould construction.

Our capability: Cost efficient moulds, Hi speed production moulds, Unscrewing moulds, Fully rotational 2K solutions.

ENGINEERING CAPACITY

JQ Plastic Mould has fully integrated design and engineering team ready to get to work on your next project.

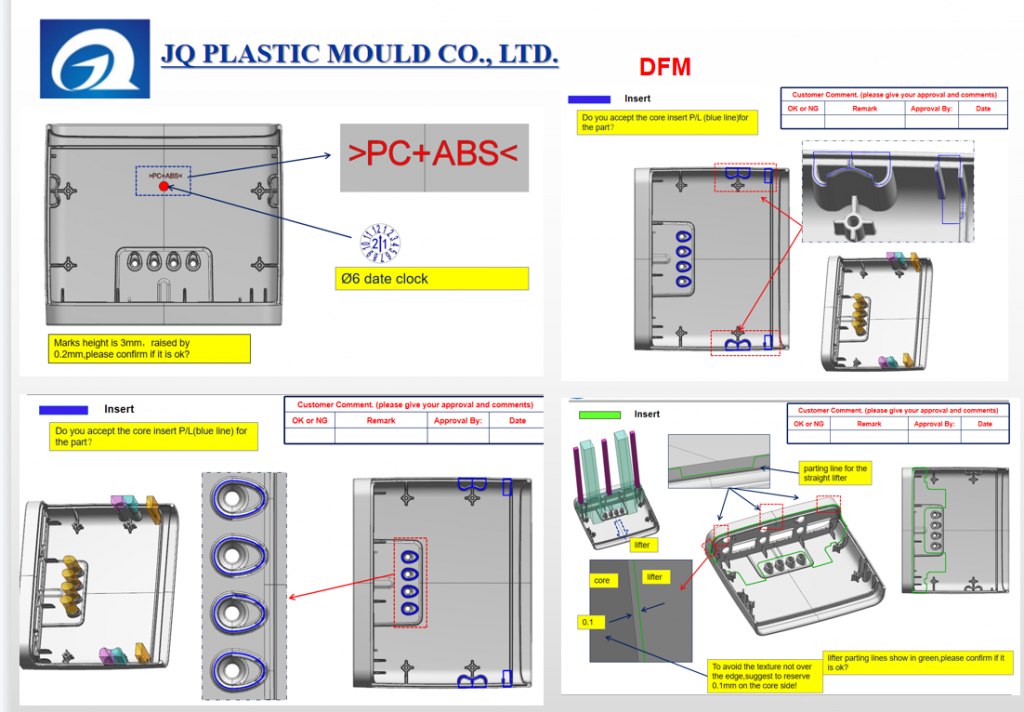

DFM

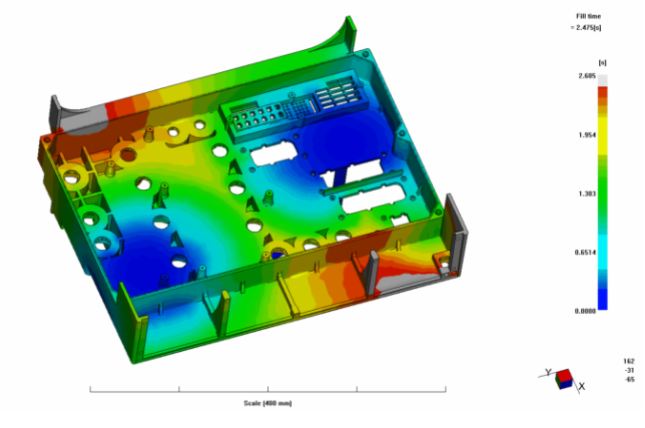

Moldflow Analysis

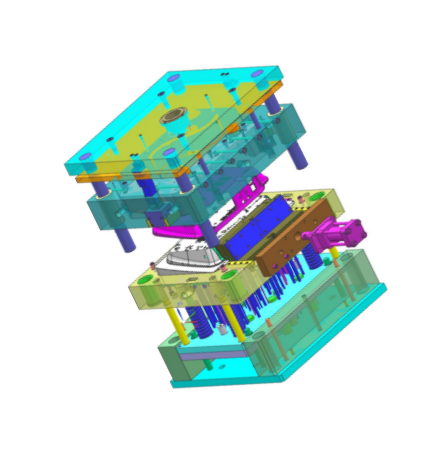

3D/2D Mould Design

PPT file to clarify issues and solutions

Currently we work with various software, such as Pro/Engineer, SolidWorks, Unigraphics, AutoCAD, Catia, etc.

PROFESIONAL MOULD SOLUTION

DFM

Our standard steps are:

Mold Specification

Surface Finishing

Parting Line Design

Draft Angle Analysis

Undercut Features

Slider & Lifter Design

Sub-insert Design

Ejector Design

Engraving Details & Locations

Gate Type, Location & Size

Mold Layout

Mould Design Manual

70 Points on the General Assembly

45 Points on Production Drawings

Covering Everything from Moldbase to Cooling to Ejection and Gate Design.

MoldFlow

Provides practical solutions to help with most injection molding problems

Optimum Cooling for Cycle Time Savings.

Optimum Gate Position for Minimum Machine Size

Position Weld Line Where You Want Them.

Eliminate Gas Traps, Sink Marks & Burning

Minimize Clamp Force Requirements

Even Part Shrinkage

Gas Injection Simulation

Reduced Warpage at Fast Cycles

EXPERT MOULD MAKING

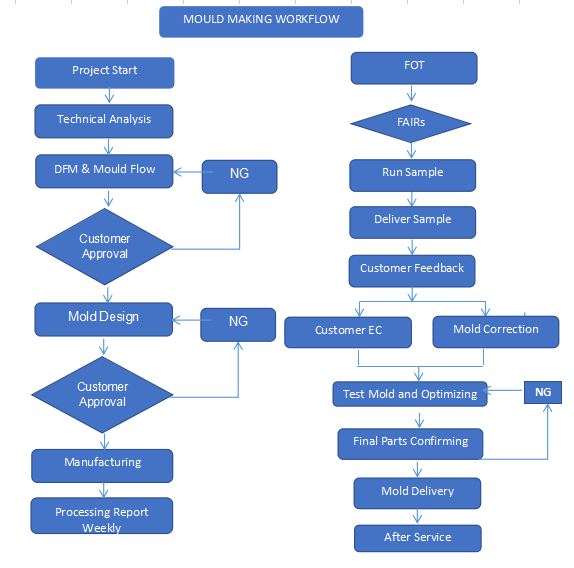

will keep you informed of the project progress throughout.

Professional project management

Detailed Manufacturing Standards

Modern Production Equipment

Weekly Process Report

CMM Inspection Report for Samples and Steel

Mold self-Checking Records Before T1

Available Live Video For Mould Trial

Sample Inspection Report

T1 Mould Problem Report

T1 Mould Trial Report

Cooling-line Checking Report